BUSINESS PLATFORMS - MINING

CEMENTATION AMERICAS COMPLETES RAISE BORE FOR SOLVAY CHEMICALS #5 SHAFT

Americas recently completed one of North America’s largest raise-bored shafts at Solvay Chemicals #5 shaft in Green River, Wyoming.Project requirements were to complete a 6,7m diameter shaft,

complete with concrete liner, from surface to a depth of 459m.

Concrete liner thickness increased as the depth of the shaft

increased, so the initial concept was to complete a pilot slash

raise with a raise bore drill and then slash from the top down to

achieve the differing diameters to accommodate concrete liner

thickness.

Cementation Americas instead proposed a full-face raisebored

shaft solution with variable diameters for each section.

In collaboration with Sandvik, Cementation Americas designed,

engineered and manufactured a reaming head that could be

diminished in diameter rather than manufacturing outside wings

with different diameters. The 8,1m diameter reamer consisted of

12 individual sections, 46 cutters and weighed 67,9 tonnes.

Once the collar excavation and lining were complete,

Cementation Americas Strata 950 Raise Drill was set up over

the collar and a 40cm diameter pilot hole was drilled. When

completed and surveyed, the pilot hole’s total deviation from

vertical was less than 10cm over its length.

The raise-bored shaft, one of the largest in North America, was

completed without a lost-time incident.

THE MINING PLATFORM MAKES A STRONG RECOVERY

The Murray & Roberts Mining platform has put the economic effects of the COVID-19 pandemic behind it and its order book has now recovered to pre-pandemic levels.“Our order book eroded in the immediate aftermath of the

global economic shutdown caused by the pandemic but

has now recovered nicely and future prospects look good

as there is a significant pipeline of new projects we’re

bidding on.” says Mike da Costa, Mining platform CEO.

The Mining platform is active in almost every major

mining jurisdiction and its major projects include the

Venetia Underground Project in South Africa, the Jansen

potash project in Canada, the Kennecott Utah Copper

Keystone project in the USA, the Oyu Tolgoi mine in

Mongolia, the Grasberg mine in Indonesia and the

Tanami mine in Australia.

Its recent acquisition of Terra Nova Technologies in San

Diego and Insig Technologies in Australia expanded the

platform’s capabilities.

Terra Nova has given the platform a foothold in the

materials handling market. The company designs, supplies

and commissions overland conveyors, crushing/conveying

systems, mobile stacking systems and in-pit crushing and

conveying systems.

“Terra Nova is a perfect fit for the platform and gives us the

capability of delivering, for example, conveying systems

of up to 12 000 tonnes per hour capacity,” says Mike. “Its

biggest market is North America, but it is also active in

South America and recently won a major contract in Chile.”

Concludes Mike, “Insig Technologies is central to our

digital strategy and our move to increase efficiencies

and safety performance. We will be using Insig’s systems

in-house initially but will ultimately market them to the

wider mining industry.”

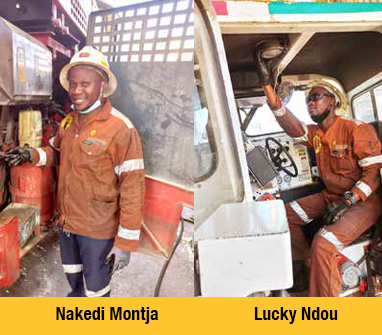

TRAINING PROGRAMME AT VUP DELIVERS SOUGHT-AFTER SKILLS

Thanks to Murray & Roberts Cementation’s training initiatives at the Venetia Underground Project (“VUP”) near Musina in Limpopo province, two community members – Lucky Ndou and Nakedi Montja – realised their dreams of becoming diesel mechanics, a qualification in high demand in South Africa.

Since the inception of the project, which will see De Beers’ Venetia mine

transitioning to an entirely underground operation, Murray & Roberts

Cementation, responsible for the sinking, equipping and commissioning

of two underground shafts and a decline shaft at the VUP site, has trained

many employees drawn from the local community in a variety of mining and

engineering skills through its learnership programme.

“We’re delighted with the success of the programme, which has seen many

employees – all recruited locally – upscaling their skills to higher levels,” says

Japie du Plessis, project executive, Murray & Roberts Cementation. “Our

approach is to employ local people for entry-level positions and then, if they

have the potential, further develop their skills to allow them to qualify for

much more senior roles, such as trackless mobile machine operators, diesel

mechanics, electricians, riggers and miners, as well as shift supervisors.”

He says that many learners, during their skills development journey, spend time

at Murray & Roberts Cementation’s world-class training academy at its Bentley

Park facility near Carletonville on the West Rand.

Lucky Ndou joined Murray & Roberts Cementation in 2013 as a general worker

in stores but was given the opportunity in 2019 to become one of the company’s

apprentice learners. This marked the start of three years of training to become a

qualified diesel mechanic. He says that his love for fixing machines, apparent at

an early age, motivated his decision to upgrade his skills. As he says, “I want to

express my technical mind through my hands.”

According to Ndou, his training was challenging at first, but became easier as he

progressed, and the subject material became more interesting. His advice to those

considering a similar journey is simple: “Nothing is impossible if you work hard and

commit yourself to achieving your goal and making your dreams come true.”

Nakedi Montja joined Murray & Roberts Cementation as a general worker on

the decline in 2019. As a child, he was always around people who fixed cars.

“I developed similar interests and fell in love with fixing engines,” he recalls.

“This is why I’ve chosen to qualify as a diesel mechanic.”

He recommends a career as diesel mechanic to anyone who is ardent about

machines and loves working with their hands. Like Lucky, he believes that

people should follow their dreams. “If you want to be happy, do not dwell on

the past,” he says. “Focus on the future and your life will reflect like a diamond.”

Du Plessis says Murray & Roberts Cementation is very proud of the

achievements of Ndou and Montja. “As a company, we are committed to

uplifting communities and one of the ways we do this is by providing community

members with skills that will last a lifetime. We’ve been working on the VUP for

roughly 10 years, and it is very rewarding to see how our training initiatives have

transformed the lives of so many employees.”