BUSINESS PLATFORM - OIL & GAS

CLOUGH’S MUNDARING WEIR UPGRADE PROJECT

The Mundaring Weir dam was completed in 1903, along with eight steam-driven pumping stations and a 557 kilometre pipeline to Kalgoorlie to address water scarcity in the goldfields.

At the time of completion, the weir was believed to be the highest overflow dam in the world, with additional works to raise the walls taking place in the late 1940s.

In order to ensure a stable future supply of drinking water amidst Western Australia’s increasingly arid climate, it was decided by Water Corporation that a further upgrade to the weir was necessary and Clough was awarded the Engineering, Procurement and Construction contract to upgrade and refurbish the weir.

To facilitate the purpose of optimising the storage of water within the weir, the upgrade required several distinct works:

• The construction of new downstream pipework, valve pits and control systems

• Relining of cast iron pipes throughout the base of the dam wall

• Removal and replacement of the architectural external platform

• Refurbishment of the intake tower roofing

• Demolition and removal of internal pipework and platforms from the intake tower

• Removal and replacement of existing intake structures and coring of a new inlet through the dam wall

• Design, fabrication and installation of an internal structural liner for the intake tower.

In addition to the inherent challenges present on a project of this scope, the importance of the weir as a source of drinking water and its status as a heritage site with daily tours presented additional risks. Heritage components such as the pump house roof and sandstone rock retaining wall were required to be salvaged, restored and reinstated.

From a safety management perspective, high risk activities on the project included critical risks, complex concrete cutting and demolition works conducted at heights, above and underwater, and within confined spaces.

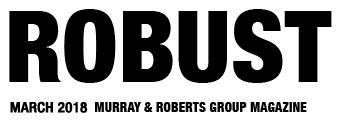

A key milestone on the project was the successful installation of a new stainless-steel liner into the weir’s intake tower, after a six-month planning period.

The stainless-steel liner is essentially a 42 tonne, 2.7 metre internal diameter, 36.75 metres long, stiffened tube and was fabricated locally in Western Australia. To install the stainless-steel liner to the intake tower, a 400 tonne crawler crane was mobilised.

The lifting operation was highlighted by four distinct events:

• Horizontal lifting and relocation of the fully assembled liner from the site welding location to the temporary crane access ramp within radius of both 280 tonne and 400 tonne cranes

• Upending of the stainless steel liner using the 400 tonne and 280 tonne crawlers to ‘top’ and ‘tail’ the liner respectively

• Vertical lifting, slewing and positioning of the liner above the round house

• Lowering of the liner into the intake tower and onto its final resting position atop three preinstalled concrete pedestal blocks.

“The project has been instrumental in allowing our client to realise their vision for Western Australia’s water supply” says Peter Bennet, Murray & Roberts Oil & Gas CEO.